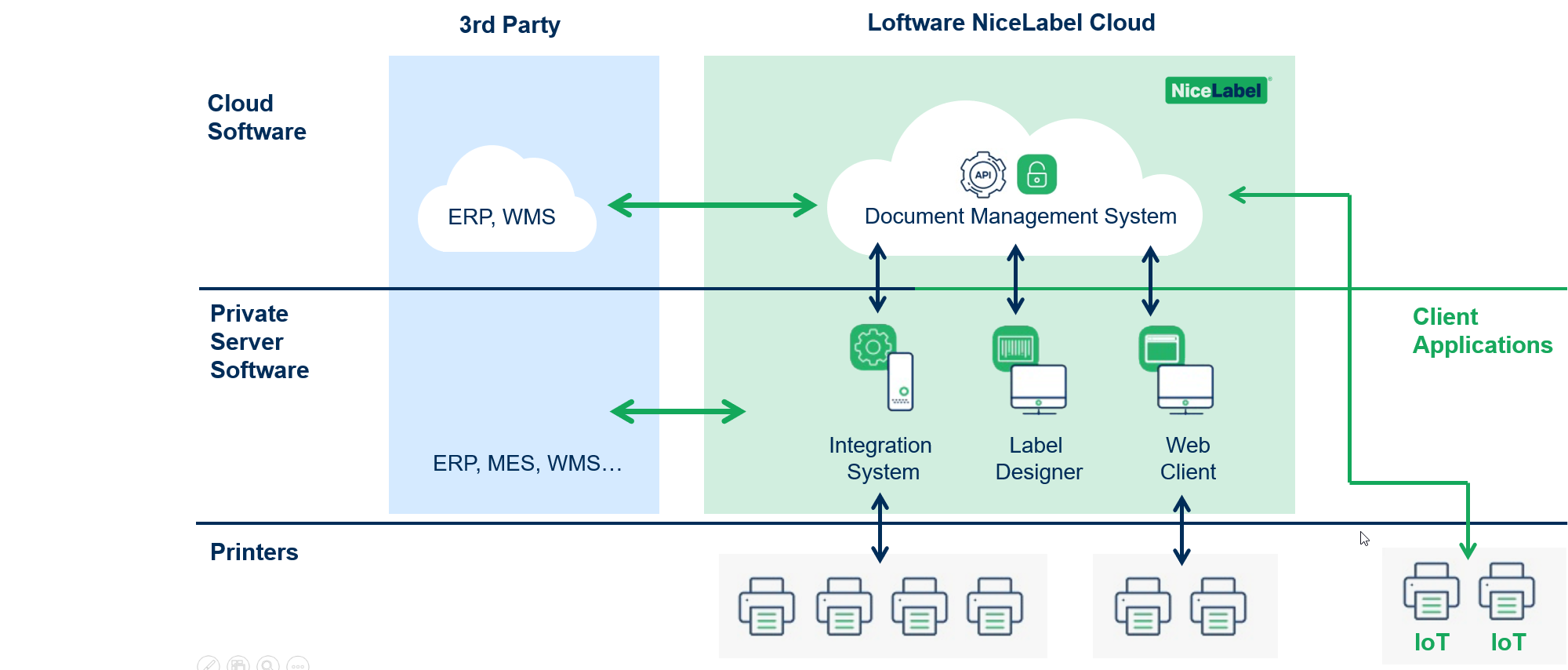

Loftware Cloud Architecture

To move a complete solution for labeling requirements to the cloud, a powerful document management system is required. It must ensure secure, high-availability data storage and enable printing on a wide variety of local printers. Access must be user-controlled and accessible from anywhere using the latest Internet browser.

The core element is of course the data storage of all documents in the cloud. These are layouts created by the designer, printing solutions generated with PowerForms, used images and other documents. Data from the ERP software and third-party systems are made available via integration and automation modules. Printing is done by using the local Loftware Print or using the web printing module.

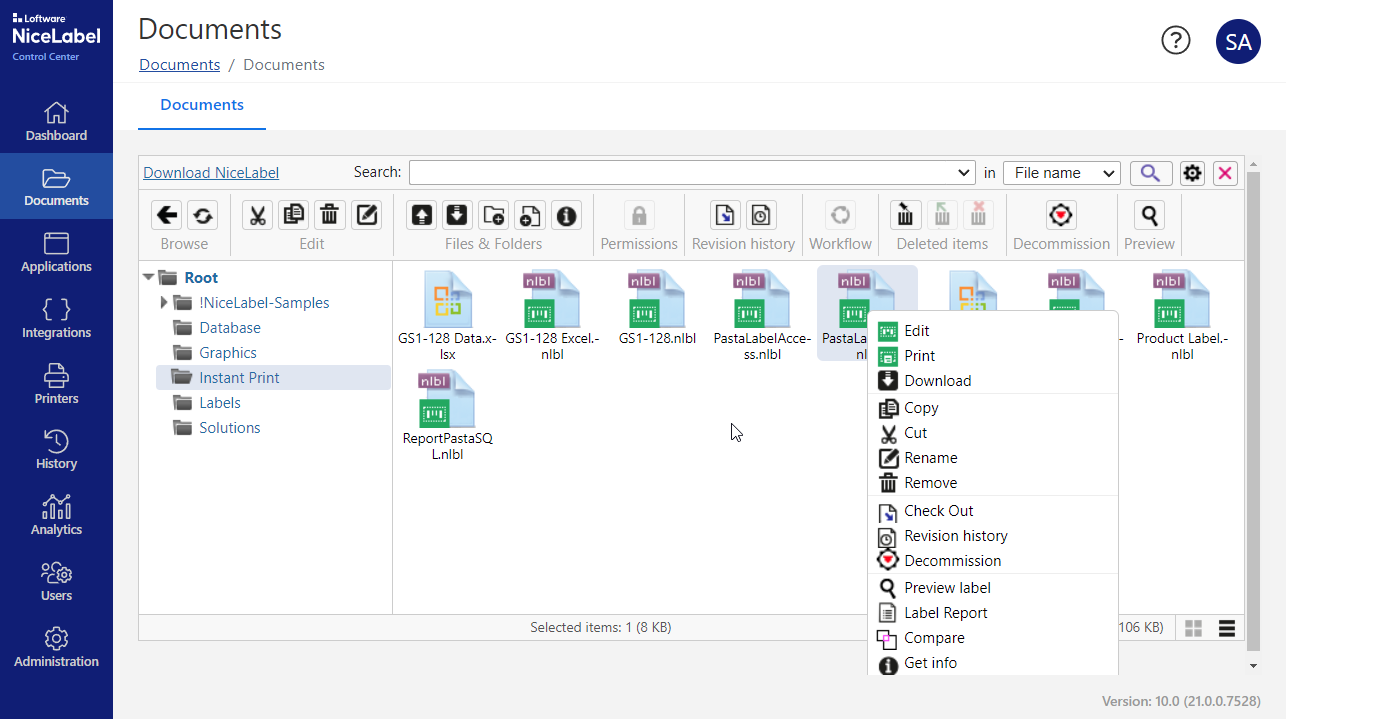

Document management

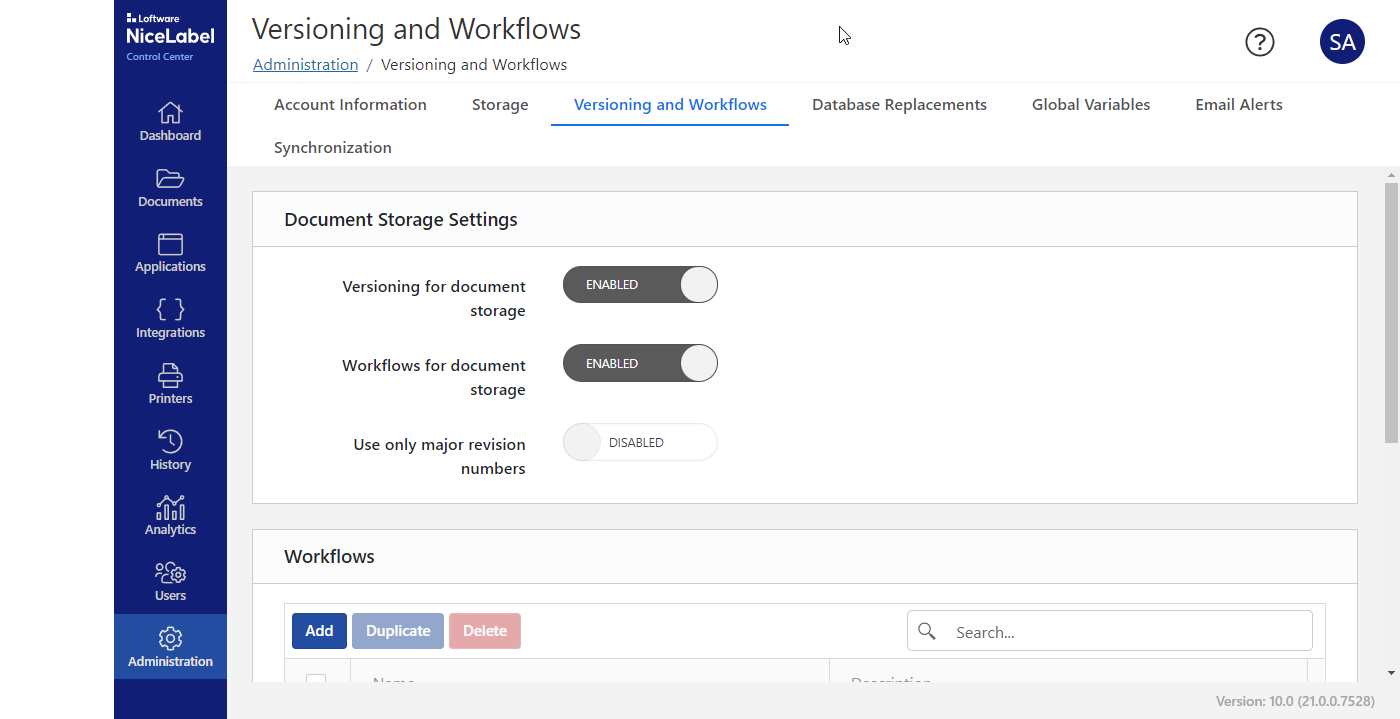

The document management in our cloud solutions offers all functions that are necessary for approved and secure printing in production. The version management is implemented by checking in- and out documents where only the latest approved revision is available in production. To control what has been printed, a history of all changes and prints in the life cycle of a document plus access to older versions makes this easy. All functions are regulated by user access rights and user groups.

Of course, with the appropriate rights, documents can be printed, edited, copied and downloaded locally. The preview, label report, layout comparison and revision history are available for an overview of existing versions. The document management can also be used for any other documents such as Word, Excel or PDF files.

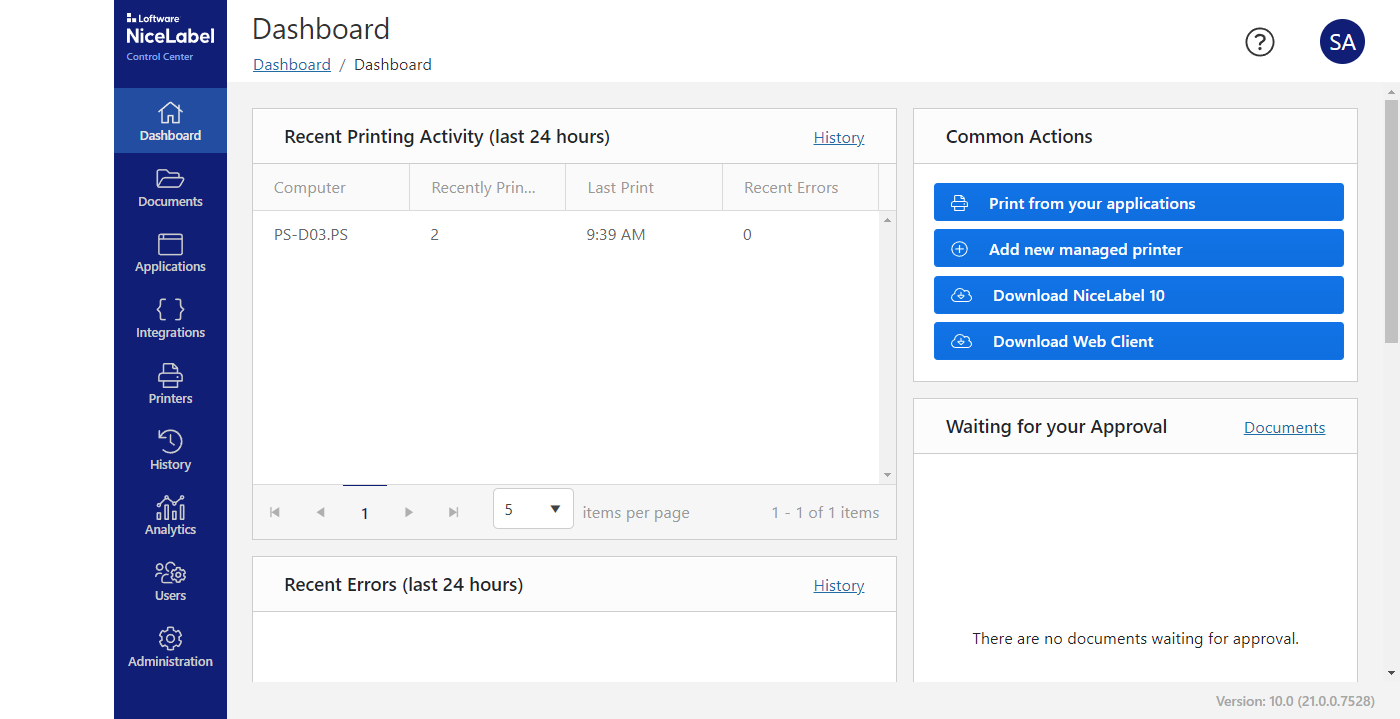

Central administration with Control Center

The Control Center is the central entry point to get an overview and manage all functions. The document management is available there including created printing solutions and integration modules. In addition to user and printer management, also administrative system settings are available in the control center. Print history and analysis diagrams helps to track product printouts and print volumes.

In the Dashboard there is access to download the Loftware software, our web printing client and printer drivers. Managed printers can be added and printing could be started via web printing or Loftware print. All functions for versioning and approving layouts including an optical version comparison is avaiable via mouse click. New printing solutions can be added to applications and integration modules can be viewed or started. Workflows, warning messages, global variables, synchronization and account data are available in the administrative area.

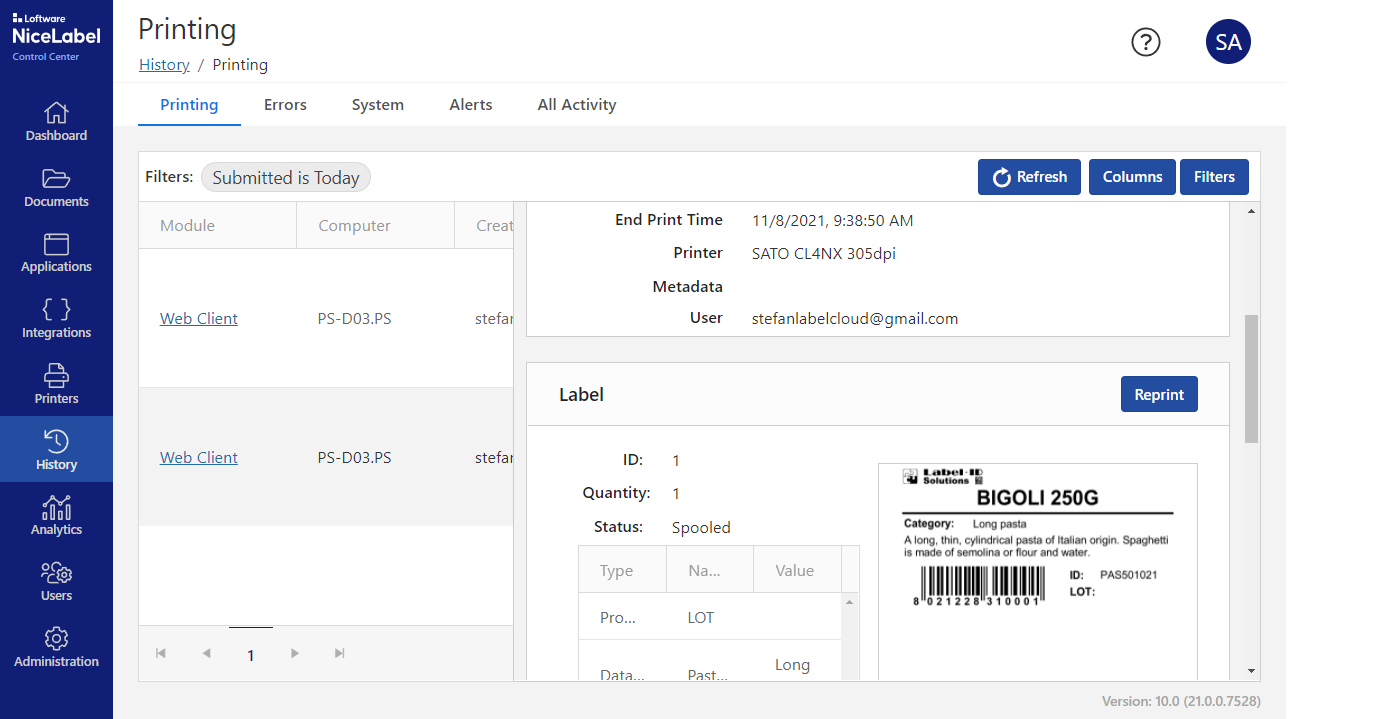

Event logging and label reprint

Consistent logging is essential for tracking printouts, troubleshooting in case of printer failures and other activities such as system warnings or logins. Required reprints are available in the print history working with the same layout revision and print data used at original print time.

The reprint function also consider serialization and offers reprint selection of only some labels from a larger print job. There is a separate list in the logging section for printer errors, system information and warning messages.

Statistics and material management

Due to licensing according the number of printers, the system knows which printers are used where and how often. It is possible to track label materials and print quantities as we know the label material. This could help the purchasing department to optimize purchasing required label material and printer ribbons.

Both pieces of information are available directly in the analysis section. Printed labels are analyzed, which printers and printer groups are used, how active are users or workstations and which of the printing solutions are started and how often. A number of filters are available for data to strip down the interesting part or period to be viewed as a diagram or in list form.

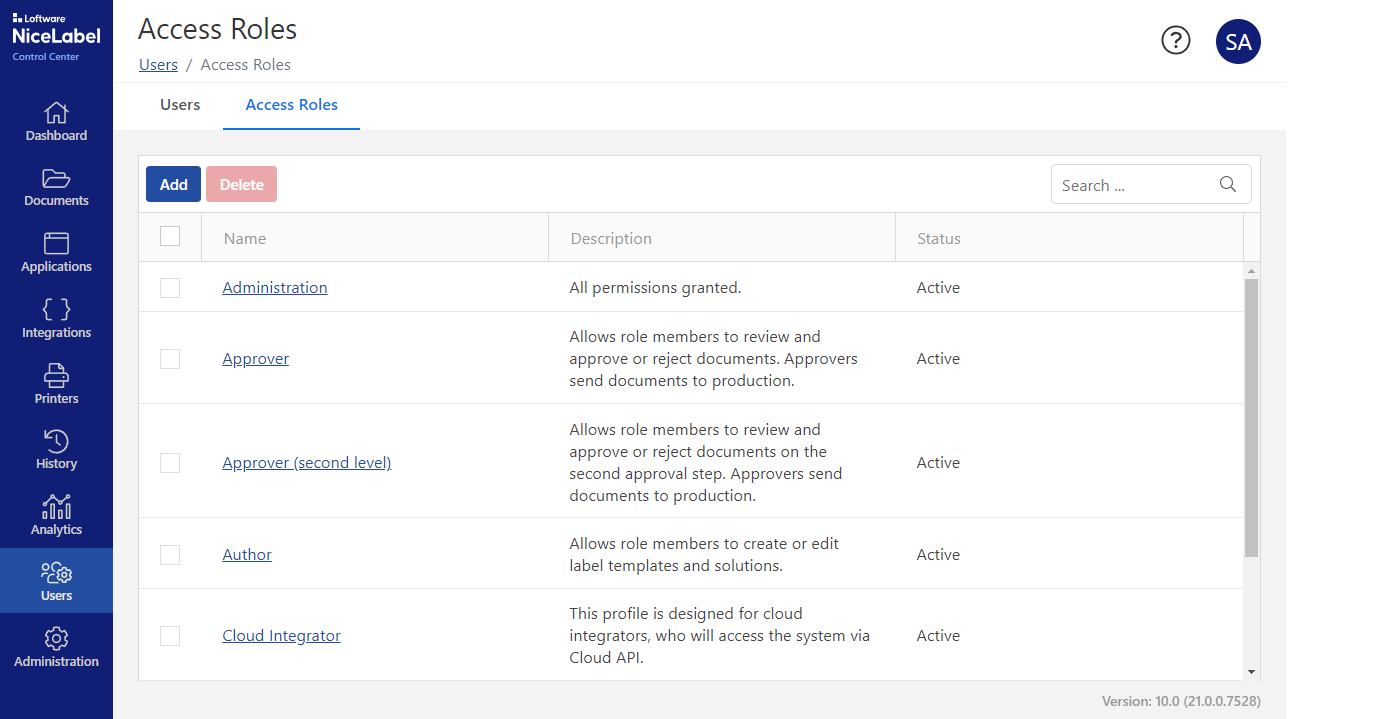

User management and access roles

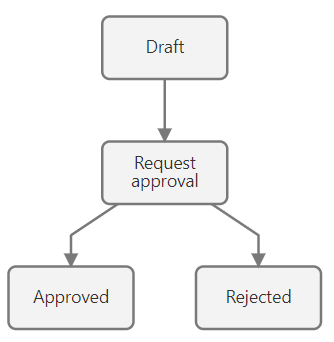

In the simplest case there is someone who creates the layouts and users who are only allowed to print in production. But very often this is not enough and a precise approval workflow is required, especially in controlled environments. Three standard workflows are already integrated in the Control Center and build on the corresponding access roles.

The access roles required for workflows can be assigned and in the simplest case is build on layout designers (author) and persons responsible for label approval (approver). The administrator role is on top level and the user (operator) role is assigned to operators in production printing. There are some special roles for installation and support (service provider) and cloud integrators.

Administration and workflows

In the administrative section all workflows can be edited to requirements, but even the predefined workflows cover most of approval processes. For special cases you can also create your own workflow and finally version control plus approval processes can also be deactivated. Warning messages, global variables, synchronization and account data are available for editing.

Important informations for activities are displayed in the dashboard and additional forwarded by mail. When configuring workflow steps, the mail addresses for the respective access roles will be added. In the workflow, you can also specify which people to notify when the status changes and which access role is allowed to perform this step.

Integration of data from SAP & Co

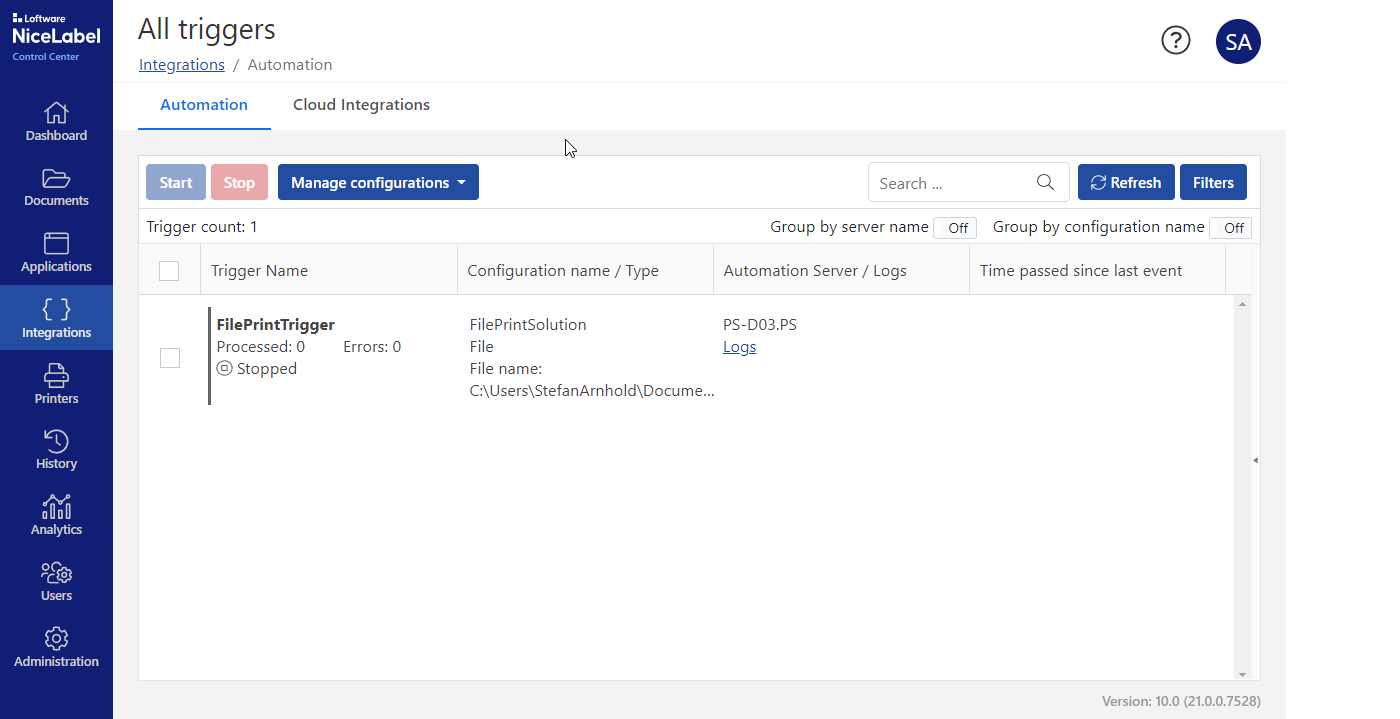

If you only want to save data that is actually printed in the cloud, this can be done quite easily by uploading file databases such as Access or exporting to Azure Cloud SQL database. In order to automate this and also with data such as weights from scales or data from test equipment, this could be solved with integration and automation. The integration tasks are handled by Windows services that work in the background or directly as cloud integration with access via the Loftware Cloud API from the Developer Portal.

Automation is implemented via Automation Manager and a wide variety of types are possible: monitored directories for reading data files, receiving data via serial interface, receiving data telegrams on LAN interface, connection via TCP/IP or HTTP as a server and data queries from web services. There are also predefined data filters for the incoming data: structured text such as CSV files or unstructured such as report pages and printer outputs. Of course, standards like JSON or XML are also included in Automation Enterprise.

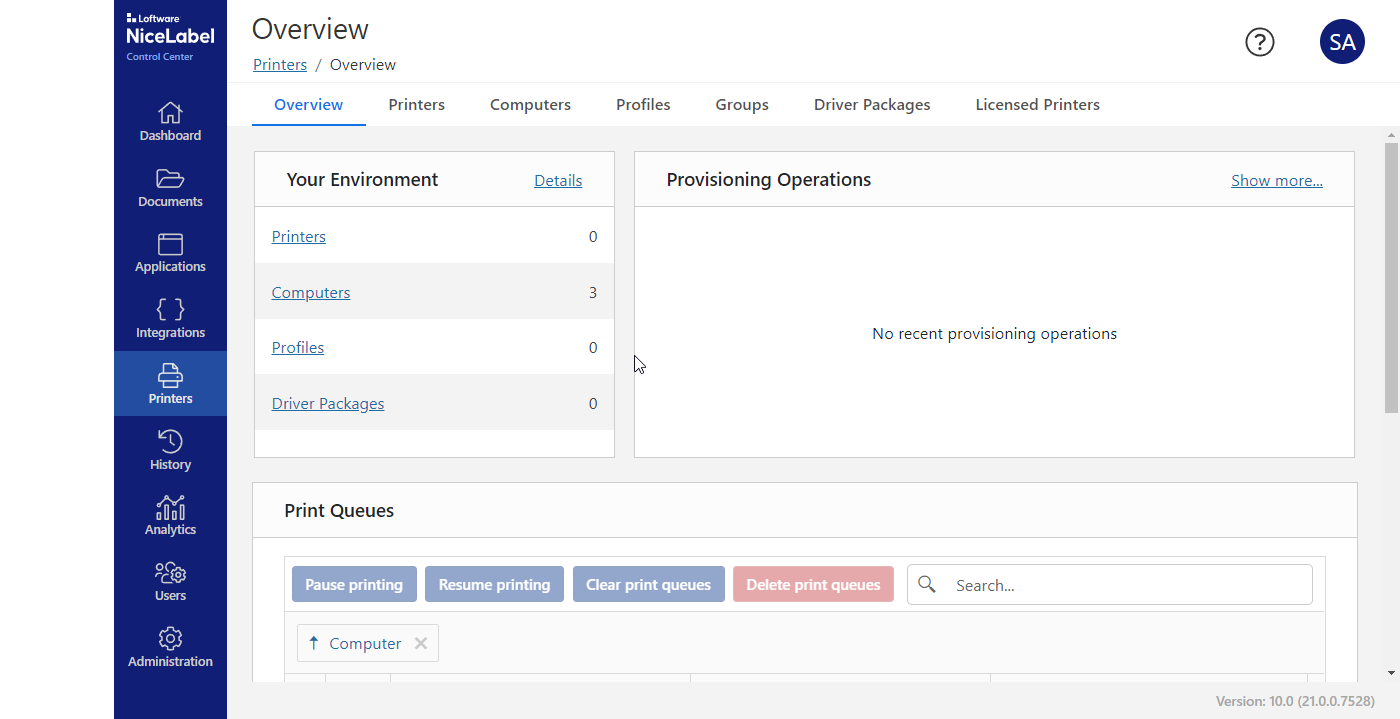

Printer status and licensing

In addition to printing labels, printers in the cloud solution are subject of licensing based on the number of used printers. A printer is defined by printer driver and connection type, so that a printer at one IP address only occupies one printer seat and can be used by several users. In addition, the control center also offers access to the current print jobs that are being processed, so that a user with appropriate rights can manage those print jobs.

Since the web printing module lists all locally available printers, it should be specified via the control center for layouts and printing solutions which printers may be used. The management of print jobs is also possible for external Windows printer drivers, but the extended possibilities of our cloud solutions are only supported by Loftware Windows driver version 10 or later.

Printing from the cloud

Printing labels from the cloud has higher requirements than local printing. The print job from the cloud should be passed on to the local printer at the highest possible speed. In addition, monitoring of print jobs and global management of printer settings are necessary due to the central administration and logging features.

In order to implement these requirements, the most important element is the used printer driver, as this is the only way to monitor and manage the printer settings. The more than 4500+ printer drivers from Loftware in version 10 offer exactly these required functions and should preferably be used with the Cloud and LMS solutions. The secure and encrypted print job data transfer from the cloud is then processed by the web printing module or Loftware print. This has the advantage of using print forms or complete printing solutions that the user can use for printing. With newer printers from SATO or ZEBRA, IoT printing is also supported where the printers connect themselves to the cloud.

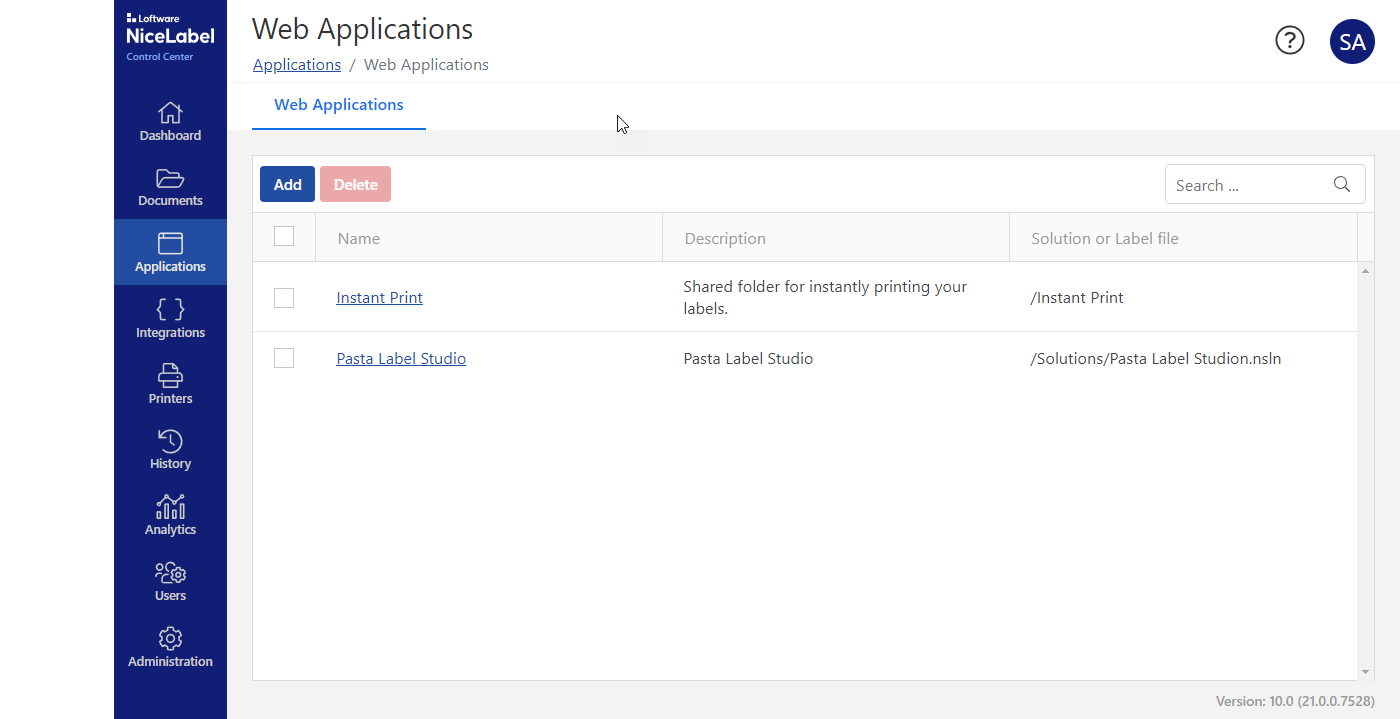

Printing solutions and applications

Correct selection of data and layouts is extremely important in production printing. Therefore, a simple printout is often not enough and data may have to be preselected including dynamic layout definition. Such scenarios can be created via PowerForms and released for the cloud. Matching authorizations and restrictions for users and user groups can then be set in the Control Center.

Applications can be created as a single solution or as a group of approved solutions and layouts. A major advantage of such applications is the possibility of access by external partners like suppliers or service providers. Via authorizations and printer restrictions, you can exactly define what the partner is allowed to use and you can revoke access at any time.

For cloud solutions we work exclusively with our partner Loftware and their Loftware Cloud products. This belongs to the various cloud subscriptions and also the local Label Management Software products.